SHARK, a global leader in motorcycle racing helmets, faced challenges due to complex global supply chains. To address these challenges, SHARK implemented Board Intelligent Planning, a user-friendly and flexible S&OP platform that enabled them to integrate sales, manufacturing, finance, and logistics functions. This resulted in improved decision-making, inventory management, and production capacity planning to better anticipate supplies and production and avoid overstocking or shortages. SHARK’s success can be attributed to cross-functional buy-in, strong leadership, and the support of a partner like Citwell.

An S&OP strategy is part of the DNA of a controlled supply chain. Board scenario planning is ideal for empowering us to prepare and secure our future.

Guillaume Escure-Herpin, Industrial And Supply Chain Director

French brand SHARK has become a global leader of manufacturing helmets, particularly for motorcycle racing. The SHARK spirit is to keep pushing technical limits and innovation so everyone can safely enjoy the pleasure and freedom of riding on two wheels. With its headquarters in Marseille and a network of factories across multiple continents, SHARK has more than six hundred employees. The organization invents and markets new helmet models every year, which are distributed by more than 5,000 points of sale worldwide.

The vulnerability of global supply chains

One of the main aspects of globalization in recent decades has been the emergence of complex global supply chains, particularly in Asia. Guillaume Escure-Herpin, Industrial and Supply Chain Director, notes:

“We have a diversified range of products and long supply chains for certain components, such as textile components which come from China and go through other manufacturers in Asia, too. In recent years, we have seen all the vulnerabilities associated with international trade. An earthquake and tsunami in Japan, floods in Thailand, and more recently the pandemic. The entire supply chain infrastructure in these countries is disrupted. How can we react quickly when we have to change suppliers and carriers? We must make accurate projections at all times.”

When Escure-Herpin first joined the company as Industrial and Supply Chain Director, his first decision was to unify all supply chain issues under his responsibility. It was an action that kickstarted a journey:

“We were able to make long-term plans and short-term projections that helped us manage our factories, decide what to make and sell, and where to sell it. However, our medium-term plans were unreliable, and this made it difficult to plan for the future.”

Board: A real S&OP platform

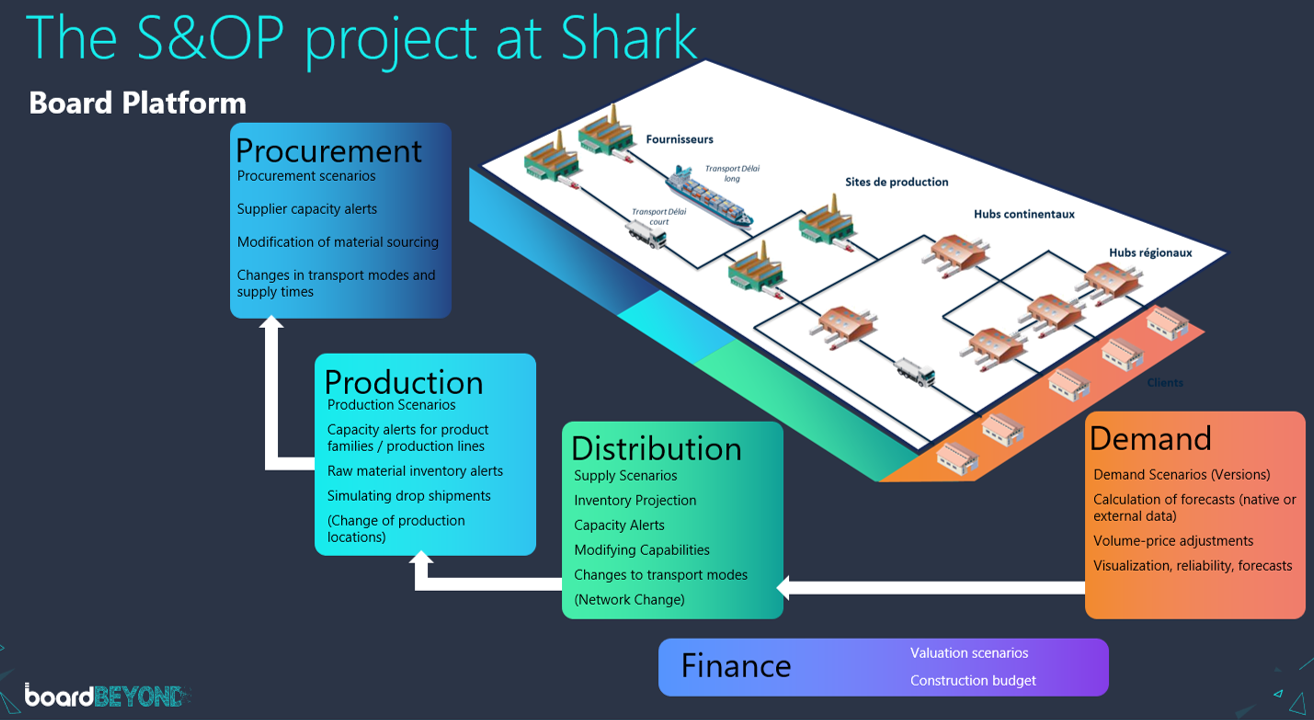

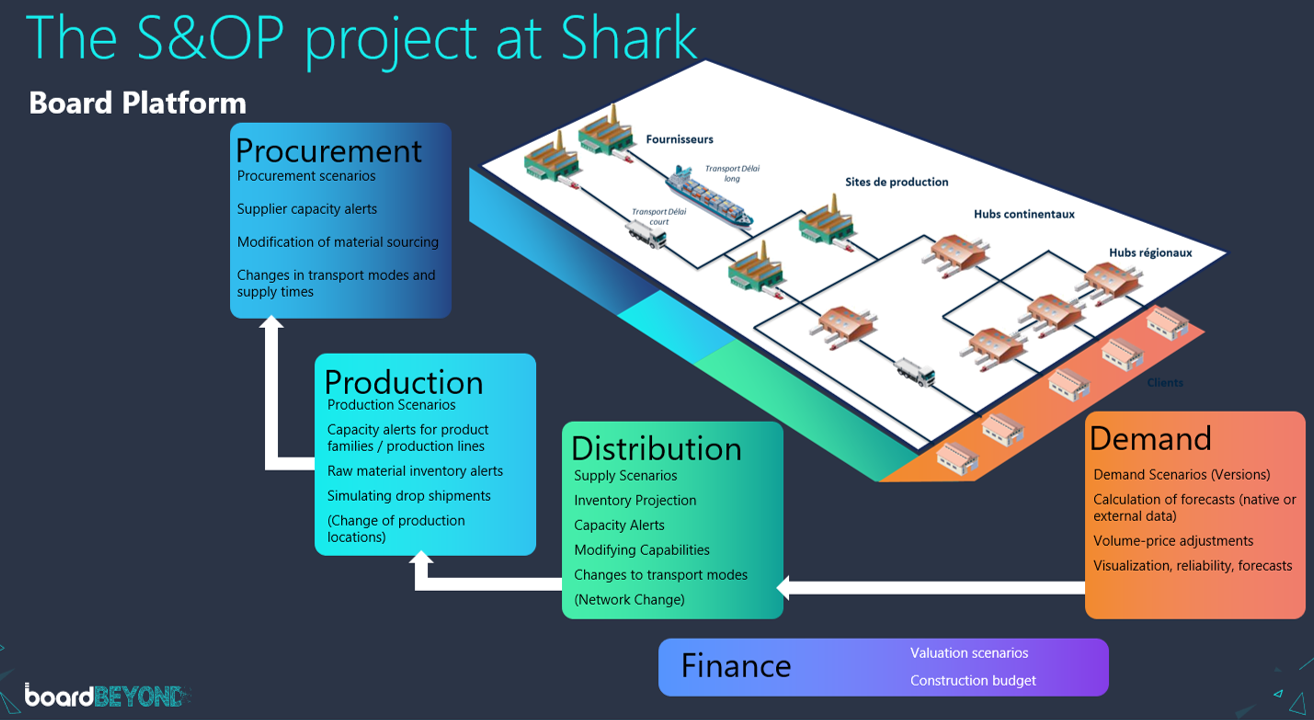

The first step was to understand project expectations. The team had not yet confirmed concrete specifics, but the main goal was to integrate all core business functions (sales, manufacturing, finance, and logistics). Escure-Herpin notes:

“We were working on a collaborative project with an aim to drive toward a single number process for the business. A phase, which we called ‘User Stories,’ was, in my opinion, the richest. It was an exercise to help us understand the individual expectations of each business function. It proved an essential moment of sharing because we wanted our teams to adhere to this new project. Board quickly became the obvious choice for us.”

SHARK’s decision to choose Board Intelligent Planning was guided by the platform’s efficient, user-friendly, and flexible approach that moves in step with change to evolve as a future-proof and future-adaptive solution.

For Escure-Herpin, Board has proven a real “screenwriting” platform:

“Starting from our sales needs, we can script optimistic, standard, or pessimistic situations and translate these for each business. Above all, thanks to alerts, we can react immediately to specific requirements. For a decision-making process, for example, an action plan at the level of the investment or at the level of the resources can be put in place. This allows us to prepare for our future in the medium-term.”

SHARK rolled out the project step by step. The demand module was the most important element to develop first to project sales forecasts, followed by the distribution modules for inventory management, manufacturing for production capacity planning, and finance for the evaluation of all scenarios created on the Board platform.

Cross-functional buy-in from all the players in the chain

From a technical perspective, SHARK needed a platform that would meet the expectations of its users while navigating the complexities of internal processes. The company had to thoroughly review its working methods, which resulted in a structuring and engaging project for the organization.

Everyone, on all levels of the business, has been largely involved. The selection commitment composed of management and sponsors was decisive. Department managers were also involved in the project via a steering committee.

SHARK has succeeded because of the way the company has executed the project. As Escure-Herpin summarizes:

“We have managed to get the main players on board in our adventure. On the human side, I was surprised by the commitment that this project generated as we looked to ensure all perspectives were included and all insights analyzed. We sensed from our teams a desire to go for it! It’s in SHARK’s DNA.”

Partner support with this type of project is also essential. Escure-Herpin concludes:

“We needed external insight, with feedback from other fields of activity and other companies. Having an integrator at your side, such as Citwell, who is familiar with the Board platform and the complexity of business processes, such as supply chain was an additional asset. Because, beyond the purely technical, IT, or software aspects, there are real business process questions to be asked.”