Transform Automotive Supply Chain Planning with Real-Time Intelligence and AI-Driven Foresight

Board’s Supply Chain Planning platform enables automotive suppliers to plan continuously, respond faster to OEM demand shifts, and protect margins through real-time, AI-powered insights.

Smarter Manufacturing: Tariff Modeling Powered by Board Signals and Foresight

Watch the 5 minute demo to learn more

Recognized by Gartner for unified platform design and by ISG for best-in-class ROI and TCO.

Board is included in the 2025 Gartner® Magic Quadrant™ for Supply Chain Planning Solutions.

Make faster, smarter supply chain decisions in a volatile automotive market.

Fortify your business

Mitigate disruption risk with integrated scenario planning across demand, supply, and finance. Automotive suppliers can evaluate tariff, sourcing, and logistics trade-offs between cost, service, and margin before execution.

Improve responsiveness

Respond faster to OEM demand shifts with rolling forecasts, AI-driven analytics, and scenario simulations that connect operational feasibility with financial impact.

Optimize profitability

Link sourcing, inventory, and cost-to-serve decisions directly to financial outcomes. Board helps suppliers reduce working capital and strengthen margin resilience in the face of market volatility.

Achieve end-to-end visibility

Gain unified visibility across demand, supply, and financial plans in one platform. Enable collaboration between suppliers, OEMs, and partners to align production and financial goals in real time.

Employ dynamic portfolio management

Segment supply chain policies by product, OEM, and risk profile. Dynamically adjust sourcing, replenishment, and portfolio mix to balance cost, service, and resilience amid changing tariffs and EV-driven demand.

Realize greater planning adaptability

Accelerate planning cycles with continuous updates and scenario-driven workflows. Planners can adjust to disruptions in real time—without lengthy replans or disconnected spreadsheets.

Shifting Gears: How AI is Transforming Planning for Automotive Leaders

An exclusive podcast presented by ISG Software Research

Industry experts from Microsoft, Wipro, and Board share how AI-driven continuous planning is transforming decision-making, enabling automotive manufacturers and suppliers to respond faster and smarter in volatile markets.

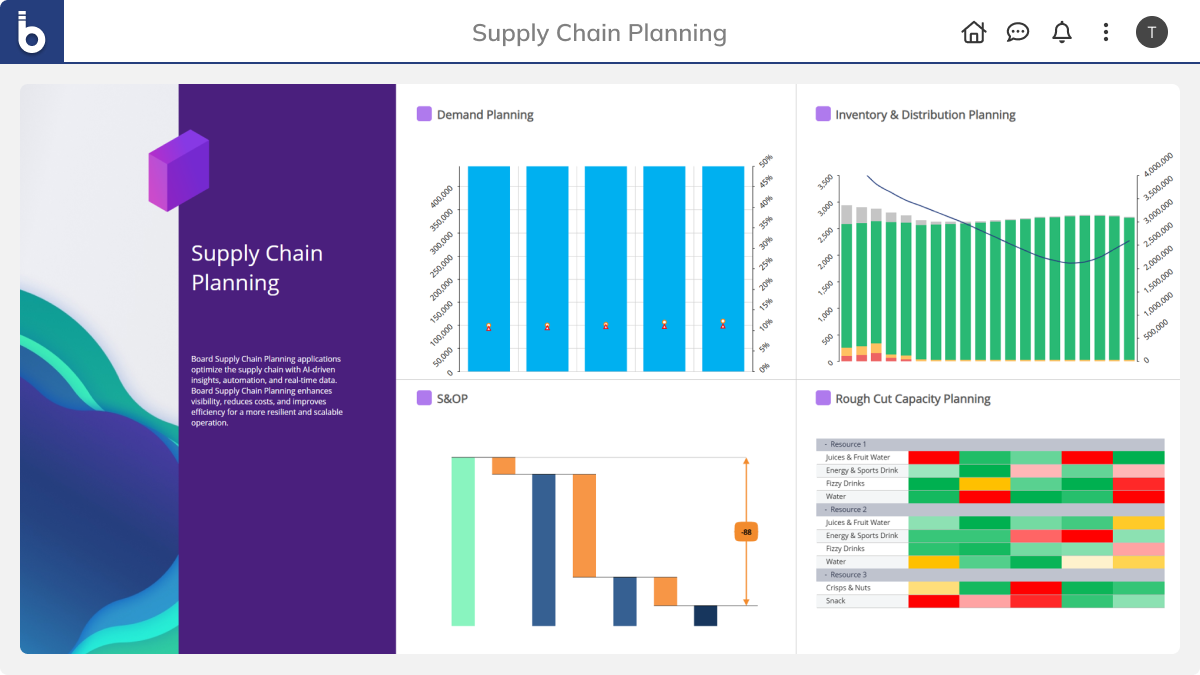

End-to-end, AI-driven supply chain planning built on one unified platform.

SALES & OPERATIONS PLANNING (S&OP)

Finance-aligned S&OP cycles with reconciled trade-offs

Board S&OP aligns strategic, operational, and financial plans across automotive supplier networks. Scenario modeling, reconciliation workflows, and executive reviews ensure every decision from production to sourcing is feasible, profitable, and aligned with OEM demand.

Explore the solution

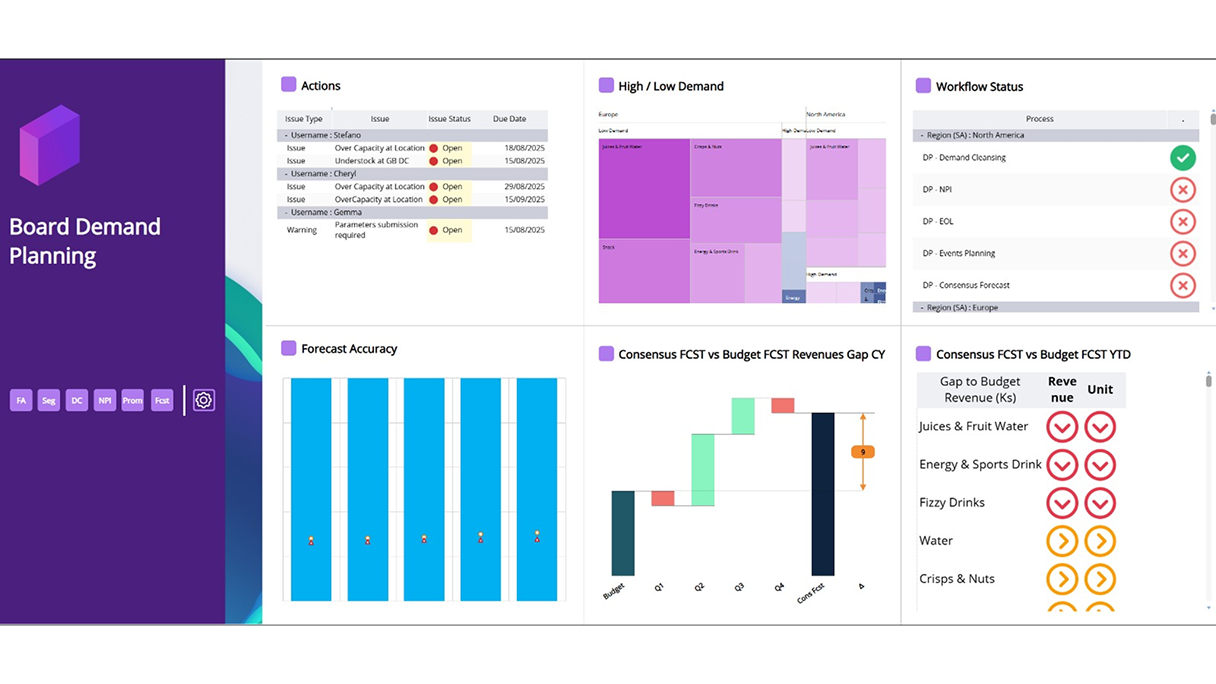

DEMAND PLANNING

Consensus forecasting enriched by AI and signals

Board Demand Planning enables automotive suppliers to anticipate OEM demand shifts with AI driven forecasting and market signal integration. Lifecycle management and scenario modeling connect forecasts directly to operational capacity and financial outcomes.

Explore the solution

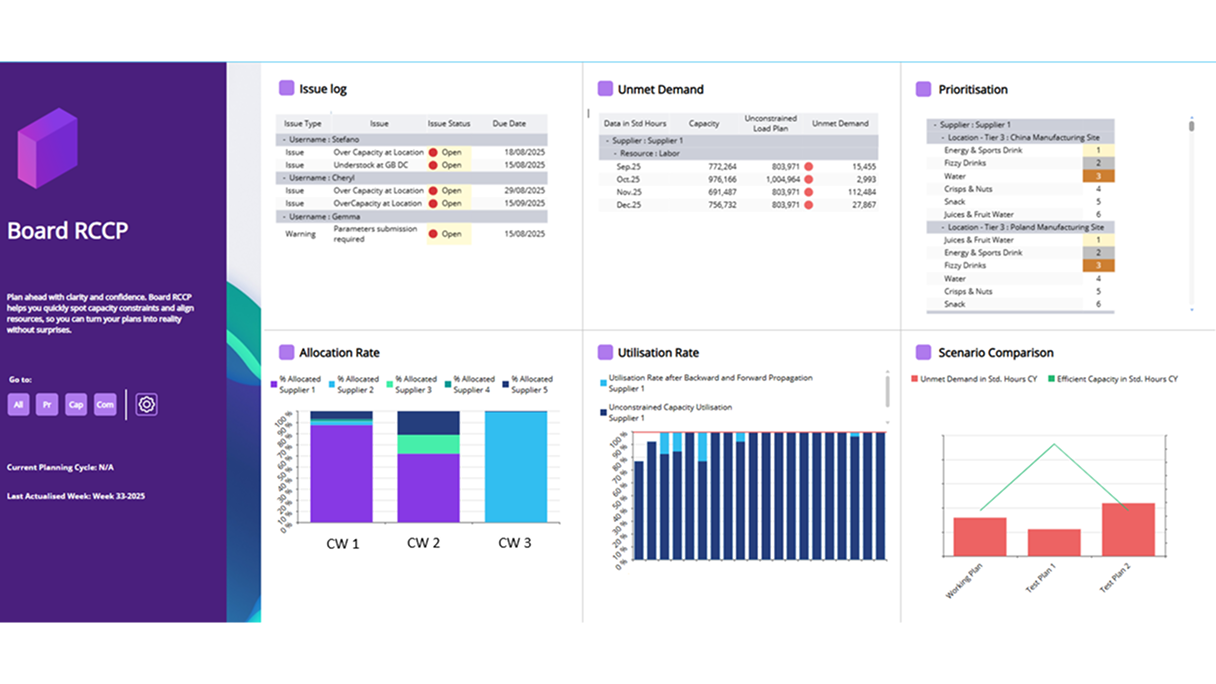

ROUGH-CUT CAPACITY PLANNING

Validate demand-supply plans against real constraints

Board RCCP validates the feasibility of supplier production plans against real capacity constraints across plants, lines, and logistics networks. Scenario planning identifies bottlenecks early, enabling suppliers to adjust schedules and resources before disruptions hit margins.

Explore the solution

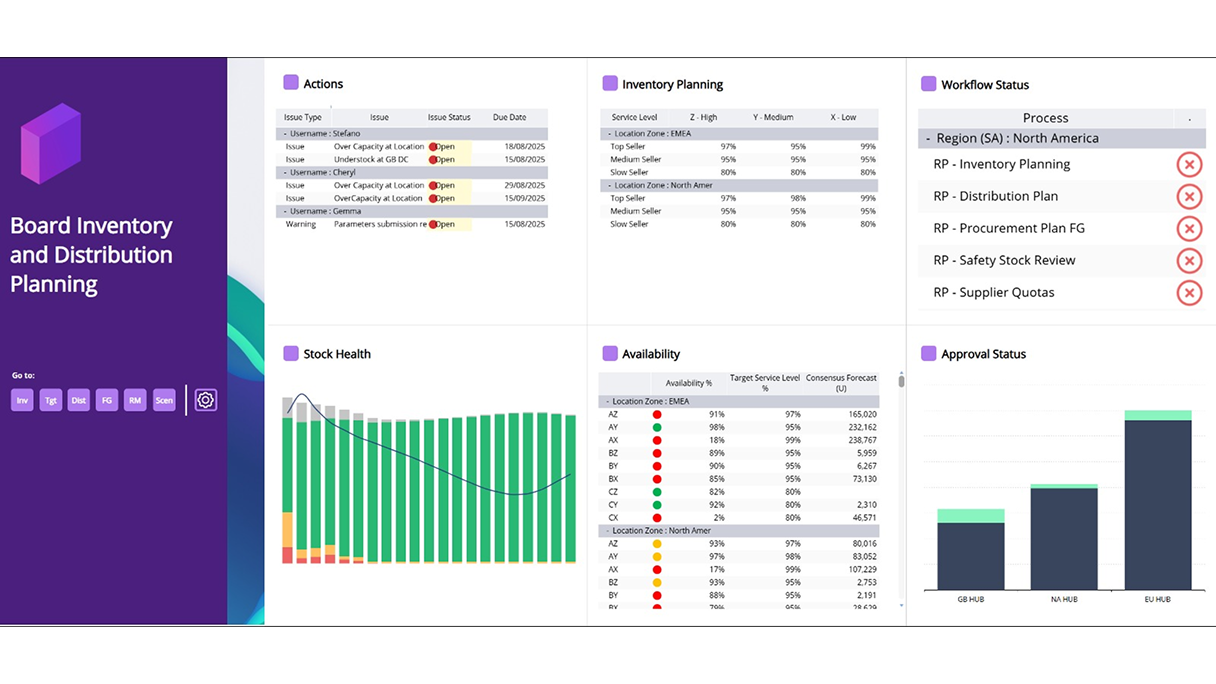

inventory & distribution planning

Advance supply planning to meet demand requirements

Board Inventory & Supply Planning optimizes procurement, production, and distribution across supplier and OEM networks. Multi echelon planning and constraint based replenishment ensure critical components and materials are available where and when they are needed at the right cost.

Explore the solutionBuilt for a continuous planning experience.

All our planning solutions converge on the Board Enterprise Planning Platform to help you make confident, aligned decisions. They transform your planning process by accelerating time to value, driving cost effectiveness, and reducing risk.

FAQs

Board unifies strategic, tactical, and operational planning across the end-to-end automotive supply chain. It connects supplier, OEM, and financial objectives within one platform, creating visibility from strategy to execution. Scenario control and governance ensure every decision stays aligned while teams adapt quickly to changing OEM forecasts, tariffs, and material constraints. This unified approach replaces disconnected spreadsheets and siloed tools, enabling faster responses to disruption, stronger resilience, and measurable improvements in service levels, margins, and working capital.

Board connects real-time OEM demand signals with supplier capacity and production capabilities in a continuous planning cycle. Forecasts, constraints, and production plans are reconciled automatically to balance service levels, cost, and capacity. Planners can instantly simulate changes — such as new tariffs or shifts in OEM demand — and see the impact on purchasing, inventory, and fulfillment plans in minutes. The result is synchronized execution across tiers, ensuring the right parts and components reach OEMs on time and at optimal cost.

AI is embedded throughout Board’s planning engine, continuously interpreting internal data and external signals such as market demand, commodity prices, logistics indicators, and tariff changes. Predictive models anticipate disruptions and propose optimal responses before they affect production or margins. Automotive suppliers gain explainable insights and automated recommendations, enabling proactive adjustments to sourcing, capacity, and pricing. This predictive intelligence improves forecast accuracy, reduces risk, and empowers faster, data-driven decisions across the entire supplier network.

Board integrates seamlessly with ERP, MES, and supplier collaboration systems through open APIs and certified connectors. It builds on existing IT investments, creating a unified data model that connects finance, supply, and OEM planning data. This interoperability supports real-time collaboration between OEMs and suppliers, accelerates deployment, and reduces IT complexity while maintaining governance and scalability for future expansion.

Board combines deep configurability with intuitive use for supplier networks of any scale. Users can tailor workflows, data models, and dashboards without code, ensuring fast adoption and local flexibility. A familiar interface provides spreadsheet-like navigation with guided workflows for planners managing complex multi-plant or multi-tier environments. IT retains full governance and security, while planners gain autonomy to run simulations, test scenarios, and collaborate seamlessly across functions. The result is flexible planning that adapts as supplier operations and OEM requirements evolve.

Suppliers using Board typically achieve measurable impact across cost, margin, and responsiveness: 10–20% inventory reduction, 15% forecast-accuracy improvement, and up to 30% faster planning cycles. Unified visibility reduces excess stock and logistics costs, improves service reliability, and strengthens working-capital control. By linking strategy, demand, and supply in one continuous planning platform, suppliers can anticipate OEM shifts, navigate tariffs, and build resilience that drives long-term profitability.

Explore the latest insights for automotive supply chain leaders.

Driving Through Volatility: How AI and Analytics are Shaping Automotive Supply Chains

Automotive Supply Chain