Supply Chain Advanced Planning & Control Platform

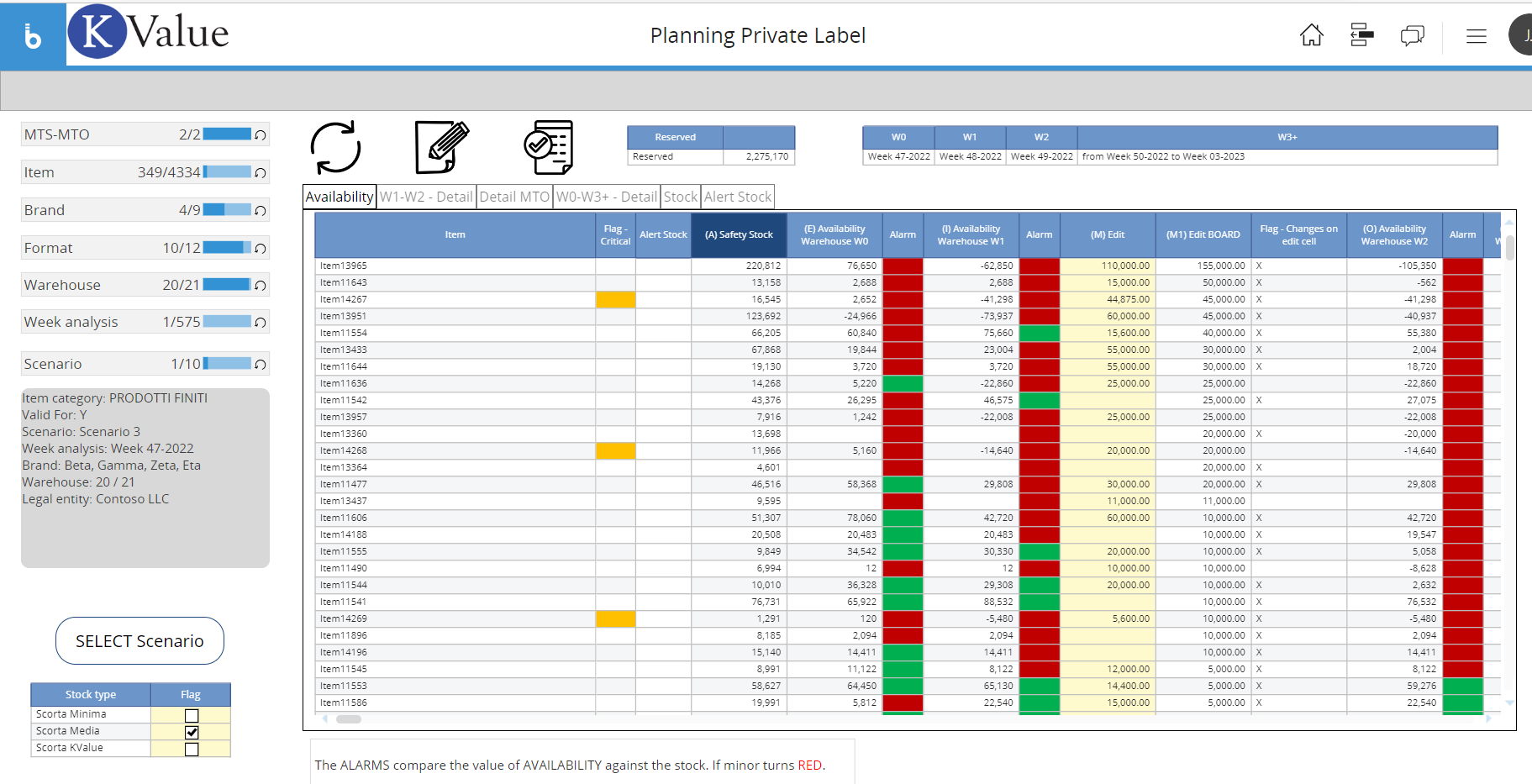

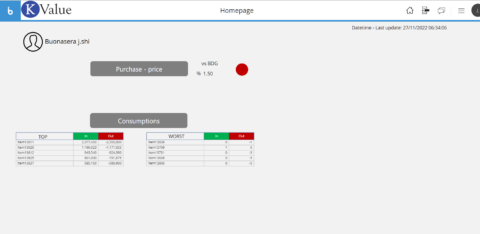

The aim of this application is to create an efficient and effective workflow between the Planning & Production and Purchasing departments to consolidate the supply chain system of companies. The application improves supply chain management in two stages:

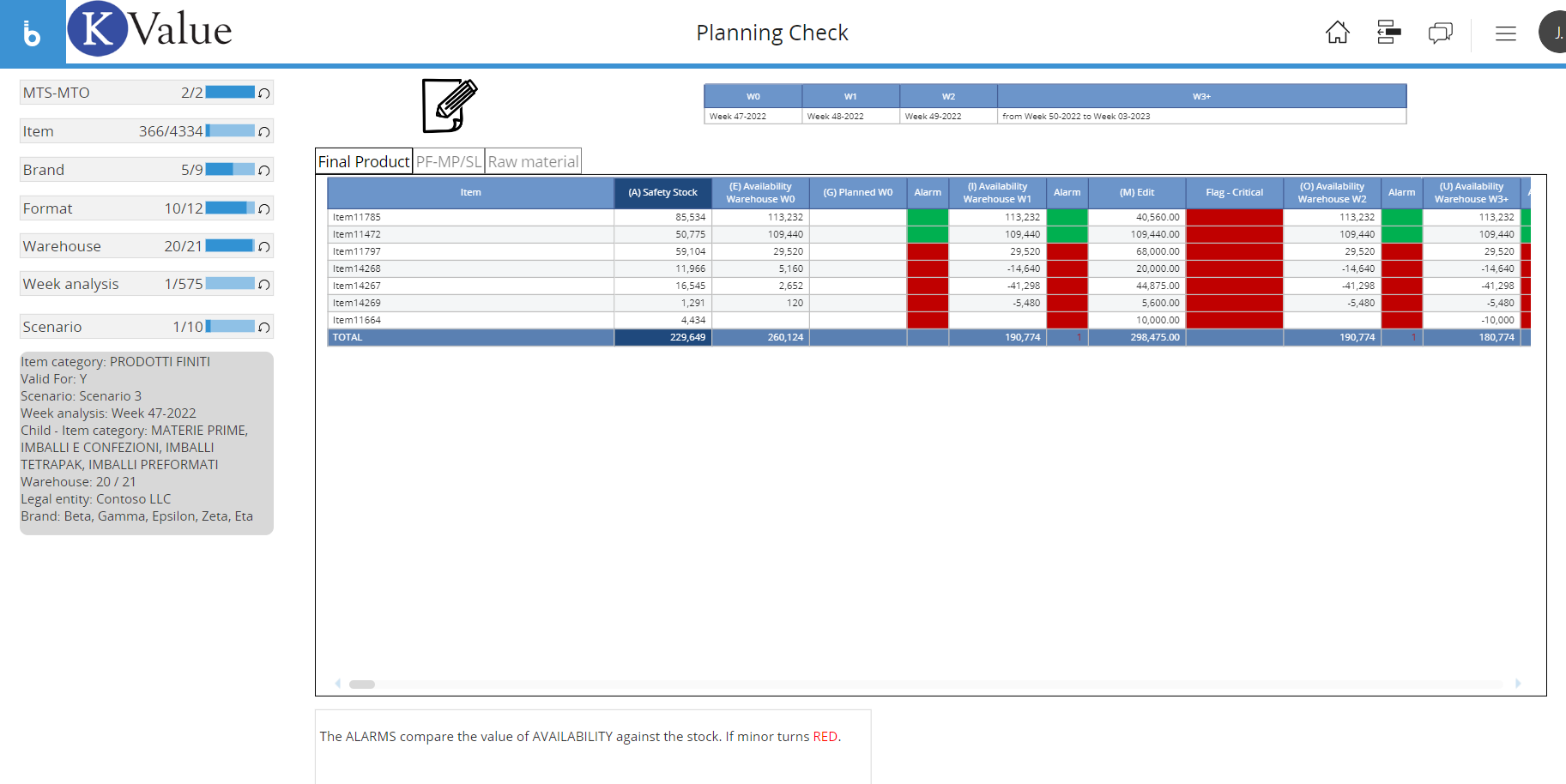

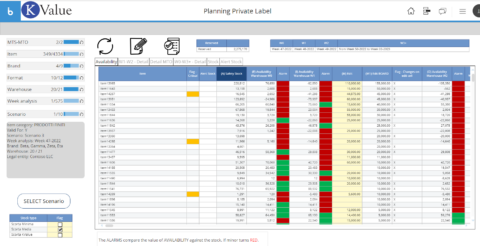

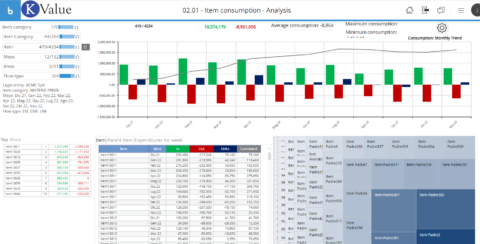

- It starts with a planning stage where initial production plans for each item are calculated and proposed according to current available stock and confirmed orders. Here, users can check for possible stock-outs and explore a structured set of data on item availability per week and safety stock at a high level of detail.

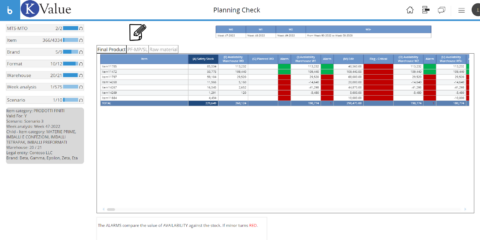

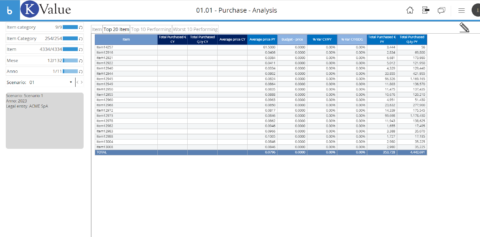

- When the Planning & Production department approves the plan, it is released to the Purchasing department. At this stage, users can see if there are enough raw materials and semi-finished goods to meet the production plan. If all the required materials are available, the plan is confirmed, otherwise users can check which items do not have enough materials in a dedicated section, insert useful working notes and therefore request a re-plan.

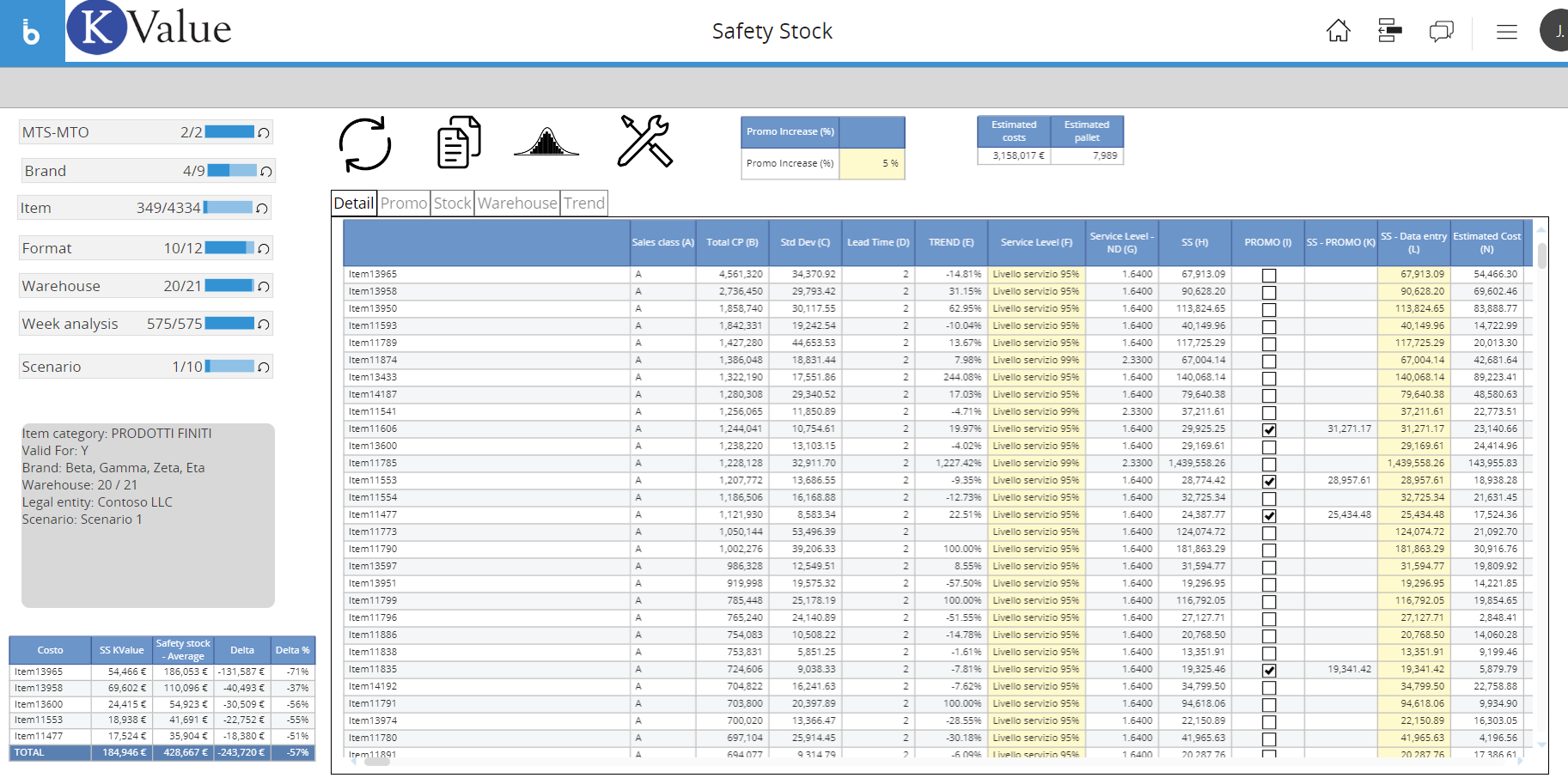

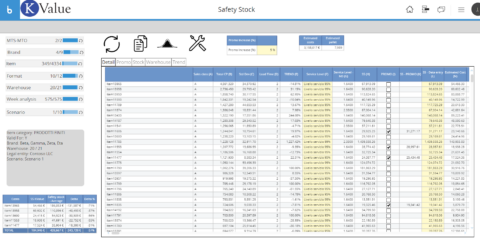

The calculation of production planning for alternative realistic scenarios is supported by the adoption of a standard safety stock model based on a normal distribution, slightly customized according to the company’s requirements and business model. The model allows the use of artificial intelligence tools such as BOARD BEAM or advanced forecasting algorithms such as TBATS or Prophet.

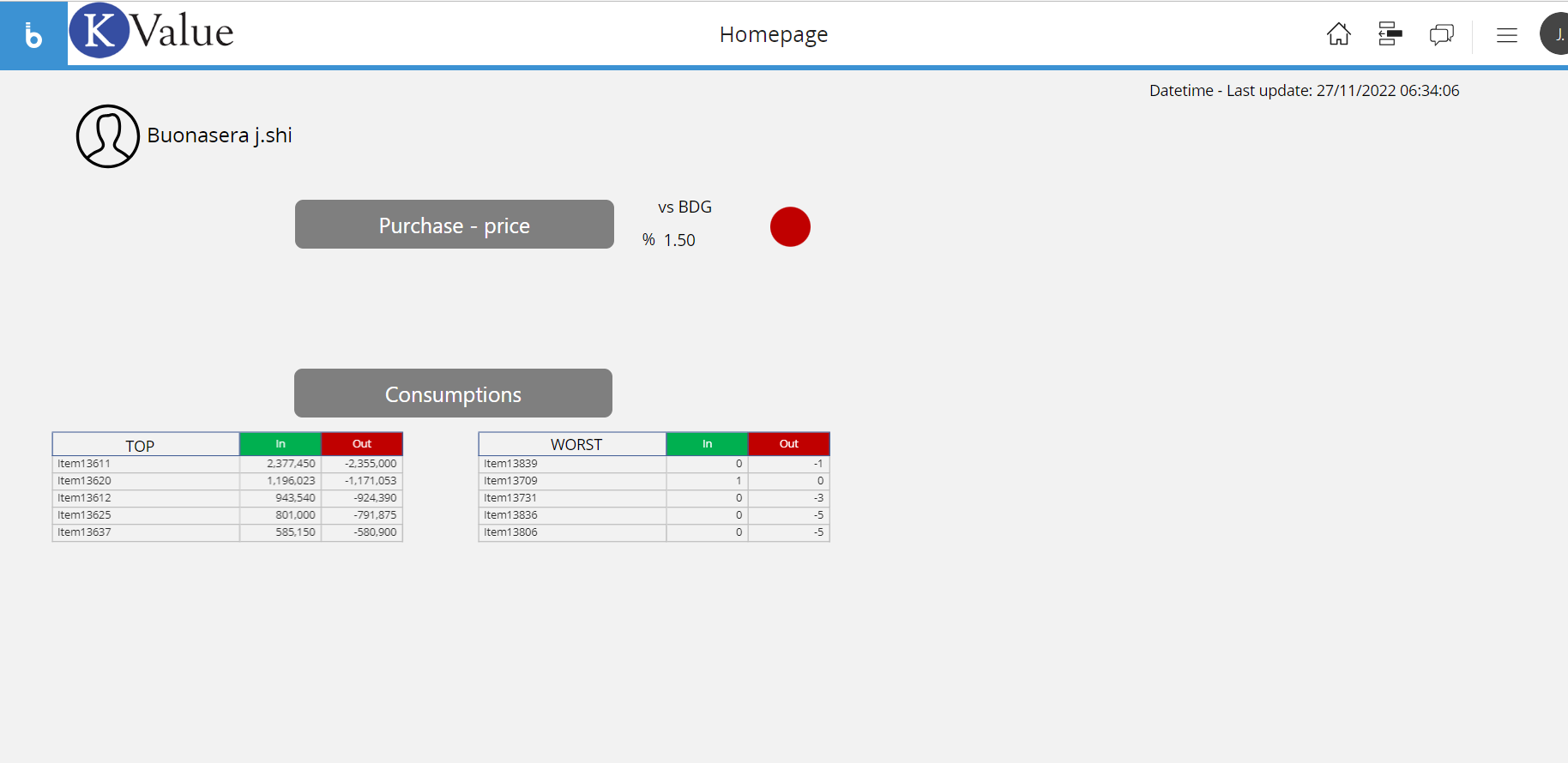

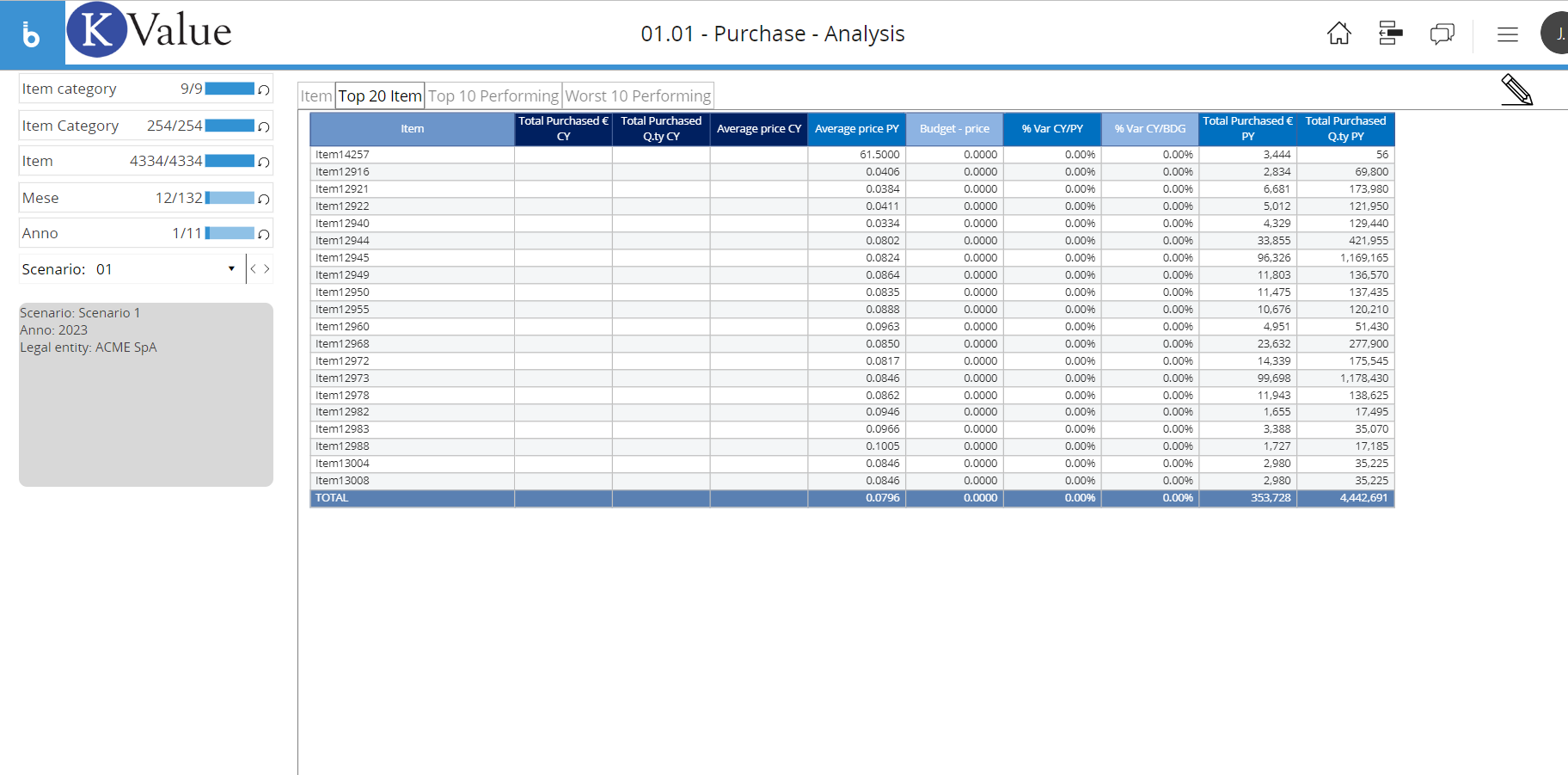

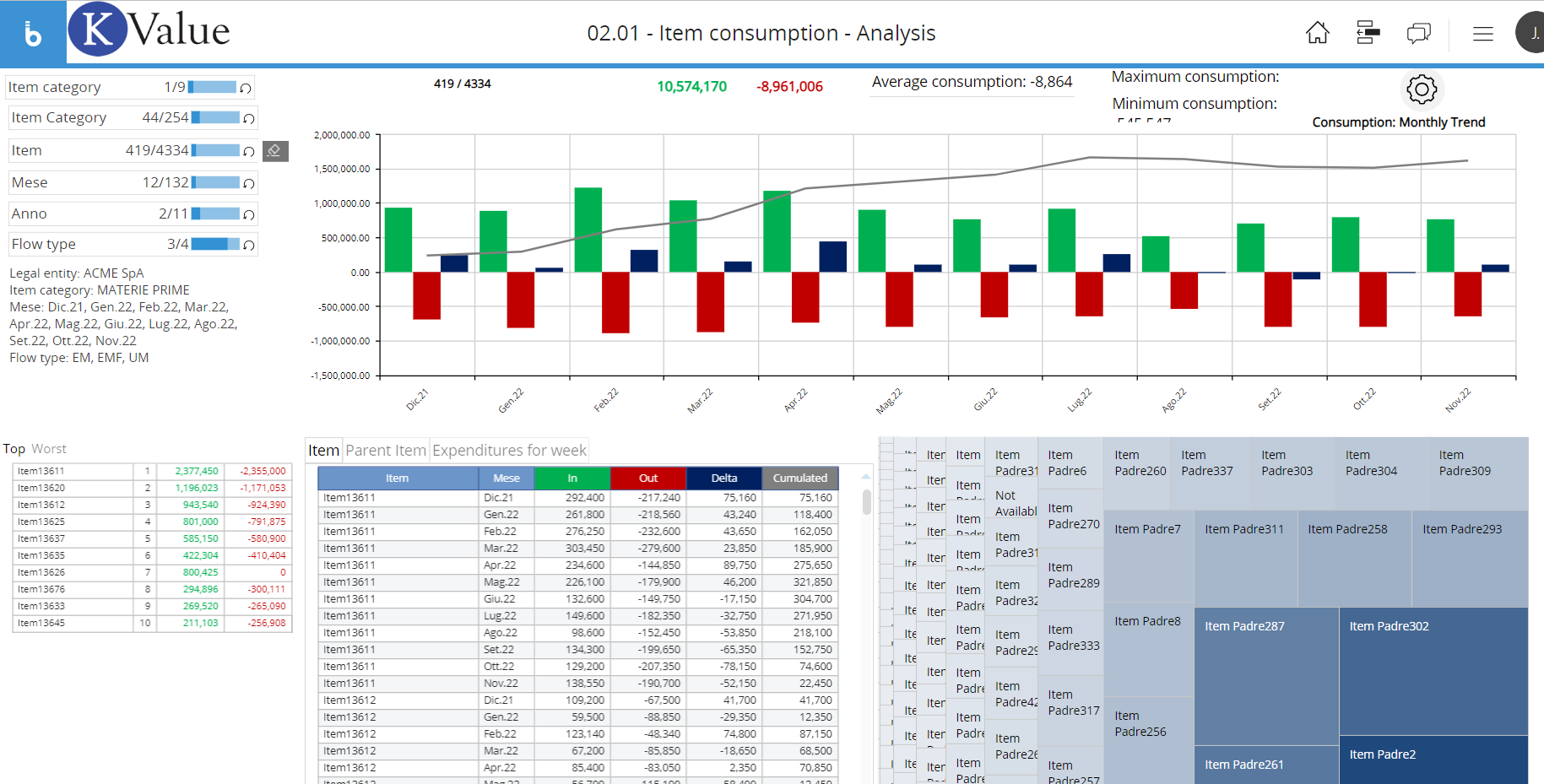

The application also provides data on the impact of promotions on safety stock, the standard deviation used to calculate safety stock, the estimated cost at stock level and material price statistics such as average price for the period, budget price and variance from the previous period. In addition, it is possible to analyze raw materials and semi-finished products in terms of cost and material flows. Users will find an intuitive line graph that shows the production consumption flows for a given period, with the ability to warn of possible material accumulations or stockouts of raw materials and semi-finished goods. It is then possible to compare the current costs with the previous year and budget data managed directly in BOARD with the data entry functionality.

Want to see this solution in action?

Complete the form and our specialists will be in touch.

Other solutions