Stock and Waste Optimization according to Sustainability Goals

Sustainability in supply chain management is becoming increasingly important for businesses as they seek to reduce their environmental impact, improve social conditions, and ensure long-term economic viability.

Sustainable waste optimization is critical for addressing the global challenge of managing waste, while promoting a circular economy that reduces the consumption of finite resources. The traditional "take-make-dispose" model of production and consumption is unsustainable and generates significant environmental and social impacts.

Sustainable waste optimization involves identifying ways to reduce waste generation, increase recycling and recovery rates, and minimize the environmental impact of waste disposal. By implementing sustainable waste optimization practices, businesses can reduce their environmental footprint, improve their operational efficiency, and enhance their brand reputation.

They can also save costs by reducing the amount of waste sent to landfill. EyeOn with the help of Board environment built a Dashboard which can help companies to manage waste and reduce CO2 emission.

A solution by EyeOn

EyeOn Stock and Waste Optimization according to Sustainability Goals solution provides company different types of dashboard which contains information about waste distribution, stock coverage, inventory planning, sustainability goals of company, scenario planning according to sustainability targets.

Main goals of using Stock & Waste Optimization solution:

- Prevent (food) waste

- Reduce food loss and waste

- Reuse and valorize food waste (ecologically & economically)

Key Features of Stock and Waste Optimization according to Sustainability Goals:

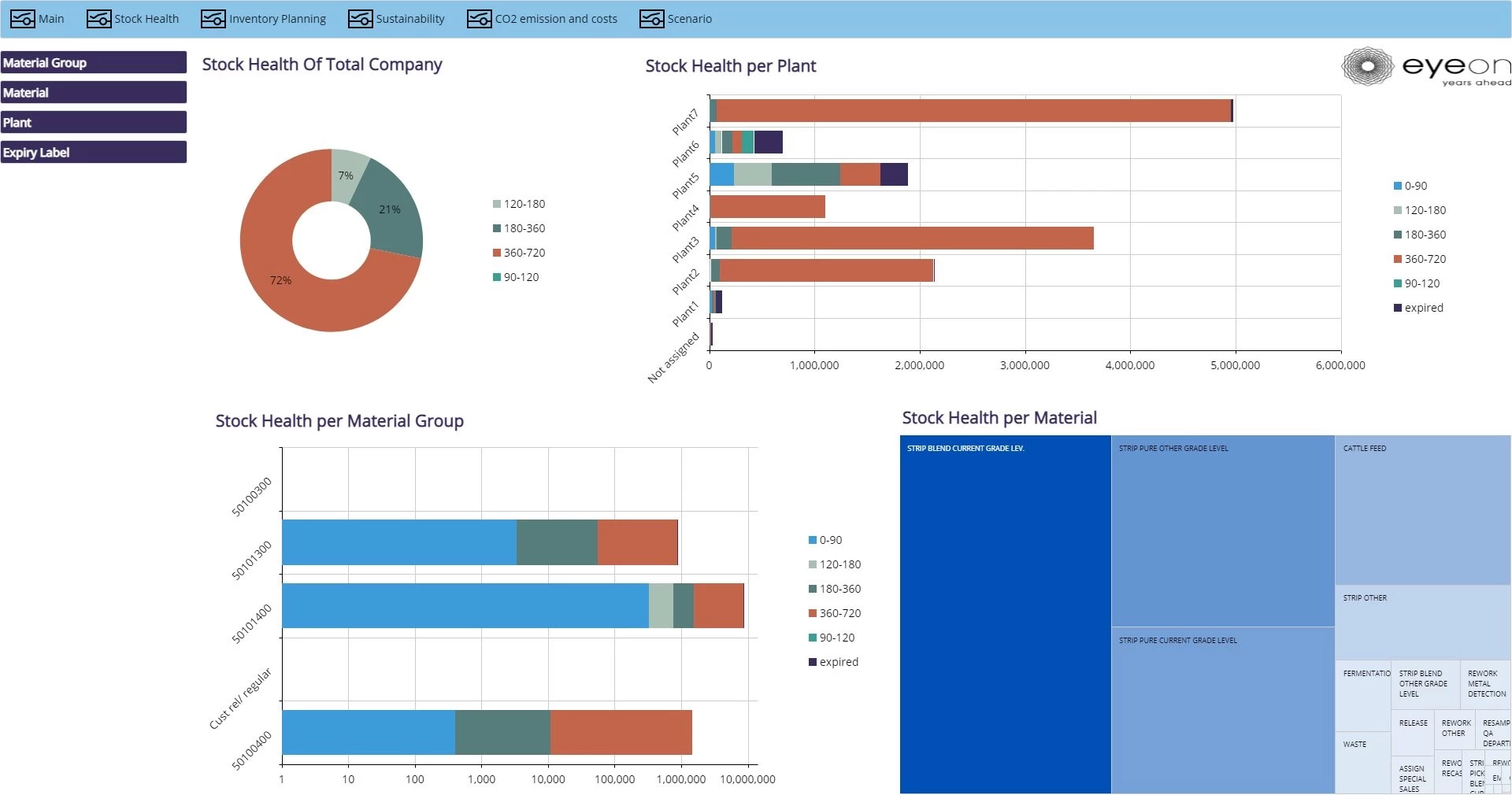

- Stock Health Dashboard which provides information about stock coverage by plants, materials, material group. This information can help companies make more informed decisions about their inventory levels, production schedules, and overall supply chain management.

- Inventory planning Dashboard which provide information about current stock, forecast, production, actuals, orders.

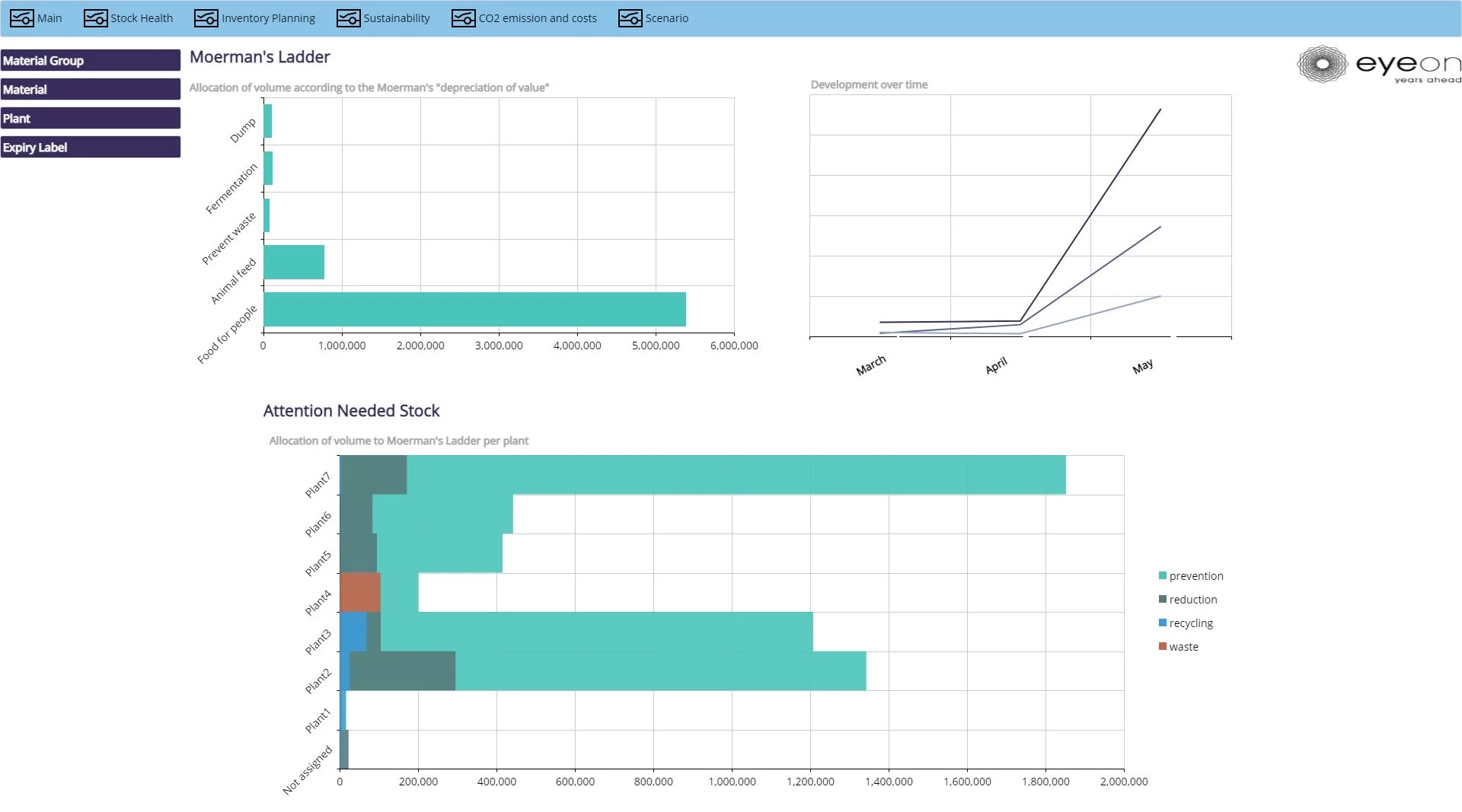

- Sustainability Dashboard that consist of waste distribution according to Moerman’s Ladder hierarchy. This feature help prioritize list of actions that individuals, organizations, and governments can take to prevent and reduce food waste. At the top of the hierarchy is "source reduction," which involves preventing food waste from being generated in the first place. This can be achieved through measures such as better inventory management, improved production planning. Achieving “reduction” level is the goal for companies with sustainability focus.

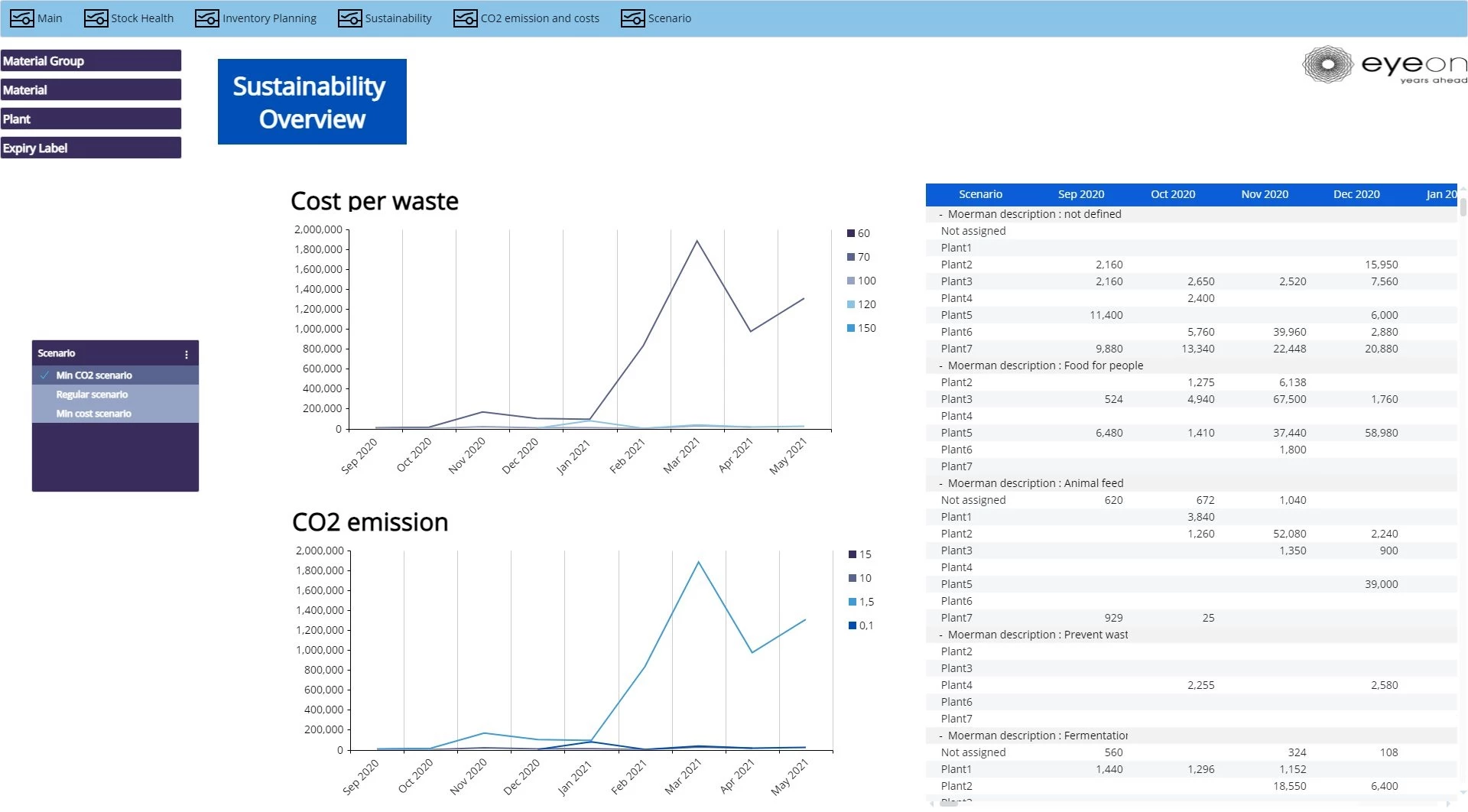

- The Dashboard for Scenarios consists of three different types of scenarios, namely regular scenarios, CO2 minimizing scenarios, and cost minimizing scenarios. By selecting a preferred scenario, the demand manager can view future forecasts, cost per waste, CO2 emission.

- The CO2 Emission and Costs Dashboard serves as an additional tool to the Scenario Dashboard, providing the demand manager with more detailed information about scenario planning.